BEST CHOICE FOR CLEANING INDUSTRY

Extrusion Line for EVA/PE Hoses (for Insdutrial Cleaning)

Flexplas designs and manufactures turn-key extrusion lines for EVA/PE hoses for the use of industrial cleaning sector. We build all the machines and tooling systems that are necessary to produce all types of “EVA/PE hose”. Flexplas industrial cleaning hose extrusion line features the latest technology enabling optimum performance at the highest line speeds. The whole extrusion system is controlled via a single master control panel including a large touch screen PLC. With our complete equipment, you can produce a wide range of hose diameters extending from small to larger, according to your need.

Flexplas EVA/PE hose extrusion line helps the customer renovate their line of production for the purpose of increasing productivity, quality, and traceability with the contemporary design and fully controlled unit with or without the operator.

The complete line is automated, equipped with modern production management systems, and constructed as energy efficient which includes the use of energy-efficient motors of the latest generation and LED lighting concepts. Furthermore, the machine has been designed to ensure a safe, easy, and time-saving operation after an accidental power failure or emergency stop. This also applies to relevant data items.

Features

- High-speed extrusion line for best quality vacuum cleaning hose manufacture

- Production of hose diameter ranges from OD ø28 mm up to ø70 mm

- Customized design to meet customer requirements

- Master control panel with Smart PLC system with color touch screen. Remote control of the complete line with one master control panel.

- Downstream equipment can be separated and installed to another production line when necessary.

Equipment Information*

- FLEXT-series EVA Extruder

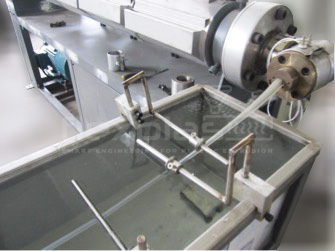

- FLEXI-COOL series Cooling Tank

- Crosshead, Dies

- Forming Unit

- FLEXT-series Co – Extruder (glue)

- Driven Conveyor System

- FLEXI-CUT series Cutter

- Tilting Table

*Downstream equipment is designed as per customer requirements. Technical specifications of the downstream equipment may change as per final product requirements.