Best know-how meets perfect craftmanship

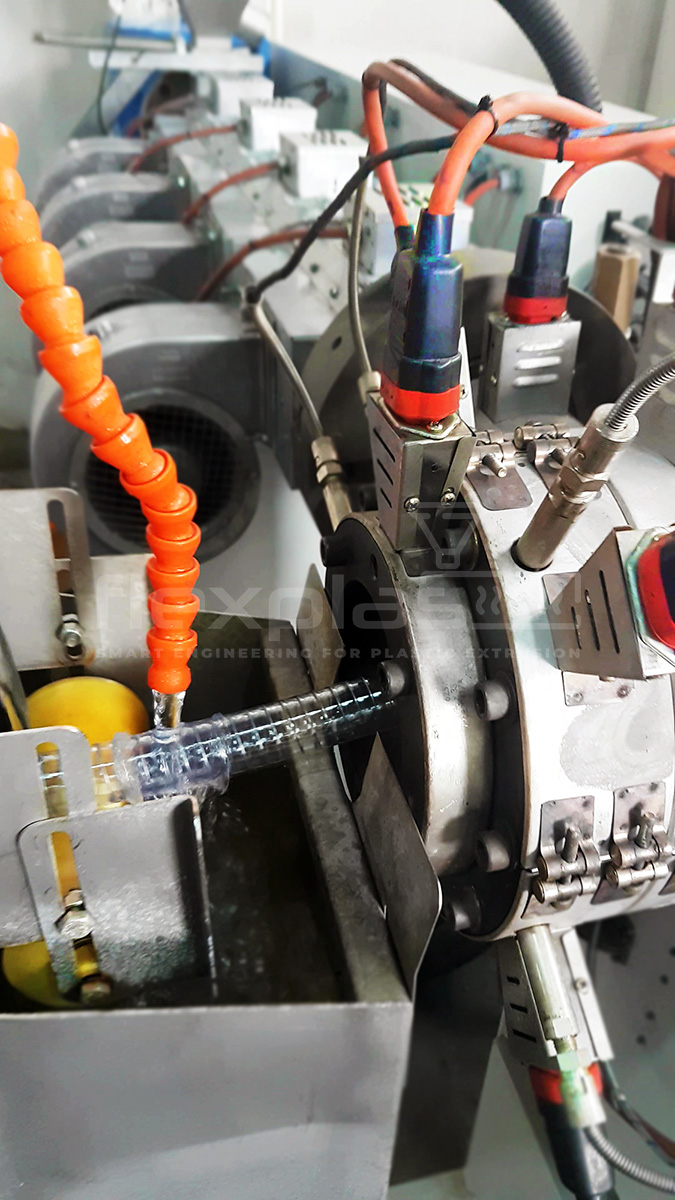

Extrusion Line for PVC Hoses with Steel Wire Helix

Flexplas designs and manufactures turnkey extrusion lines for flexible PVC hoses reinforced with a spring steel wire and PVC coated spring steel wire helix. That is, we build all the machines and tooling systems that are necessary to produce “PVC-steel wire hose”. We realize this with our technological know-how and perfected craftsmanship. With our complete equipment you can produce a wide range of hose diameters extending from small to larger, according to your need. The complete line is automated, equipped with modern production management systems, and constructed as energy-efficient which includes the use of energy-efficient motors of the latest generation and LED lighting concepts. Furthermore, the machine has been designed to ensure a safe, easy, and time-saving operation after an accidental power failure or emergency stop. This also applies to relevant data items.

Features

- Optimized speed for best quality hose production.

- Production of hose diameter ranges from ID ø10 mm up to ø203 mm

- Optional textile reinforcement for the hose in addition to steel wire for heavy-duty applications

- Customized design to meet customer requirements

- Master control panel with Smart PLC system with color touch screen. Remote control of the complete line with one master control panel

- Downstream equipment can be separated from the line and can be installed to another production line when necessary

Equipment Information*

- FLEXT-series PVC Extruder

- Wire Unwinder/De-coiler (Optional)

- Wire Feeding Machine

- Crosshead, Dies

- FLEXI-COOL series Cooling Tank

- FLEXI-CAT series Caterpillar Haul-off

- FLEXI-COIL series Coiler/Winder

*Downstream equipment is designed as per customer requirements. Technical specifications of the downstream equipment may change as per final product requirements.