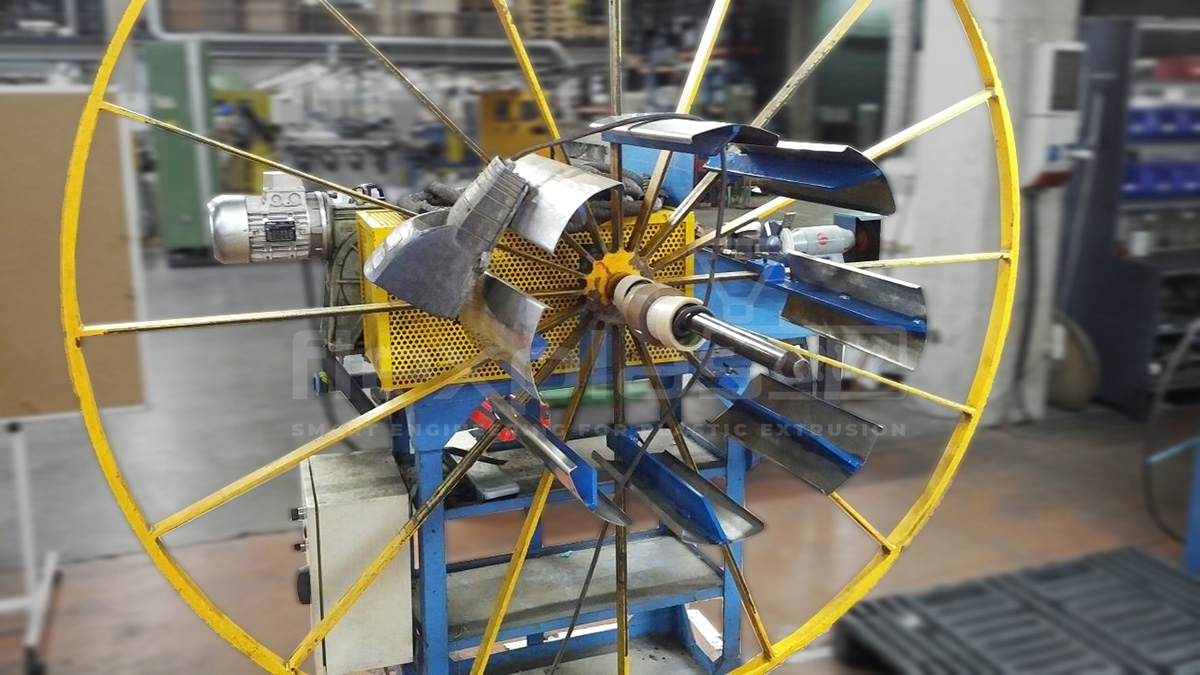

Easy and cost-effective winding

Flexplas FLEXI-COIL Series coiling/winding machines are perfect solution to an easy and cost-effective means of winding hoses and tubing. We offer a broad range of automatic coilers, fully or semi-automatic, that are customized to suit your production requirements.

Easy integration with your extrusion line, winding at high line speeds

All Flexplas winders have sturdy design, long lasting components, low maintenance, and are easily integrated with any existing extrusion line. Our coilers wind small flexible extrusions with little-to-no friction or winding tension. Tension and speed are precisely controlled throughout the winding process. The traverse width and pitch are fully adjustable ensuring a clean and neatly wound coil. Flexplas coiling machines are easily adaptable to winding hoses at high line speeds. The fully automated process transfers the product to the new reel without operator involvement or process disruption.

Application

Downstream equipment to extrusion lines for PVC hoses, braided hoses, garden hoses, medical tubes, pneumatic tubes, corrugated pipes, flexible profiles, etc.

Features

- Single and Dual coiling stations

- Welded steel profile frame

- Automatic adjustment for speed & tension

- Fully adjustable traverse width & pitch

- Good coiling quality by using latest drive technologies

- Coiling arms adjustable for the desired inner diameter and width of the coil

- PLC touch screen operation

- Optional servo-driven traverse motion, spindle rotation, and spindle speed

- Automatic cutting of hose/profile. Tensionless winding with automatic cut

- Best accuracy with optional servo control

- Suitable for a range of coil formers and reels

- Distortion-free end-product

- Operating parameters can be saved within a recipe

- Compact design to fit easily into every production line

- Clean, clear design for easy operation

- Compliant with the latest EU/US standards

- Conformity to CE

Options

- Many options to help modify the coiler to special customer requirements

- Spare set of collapsible coils

- Modifications for use of customer coils

- Additional product tips

- Manufactured to meet medical requirements

- Strapping units using PP band

- Automatic coil ejection