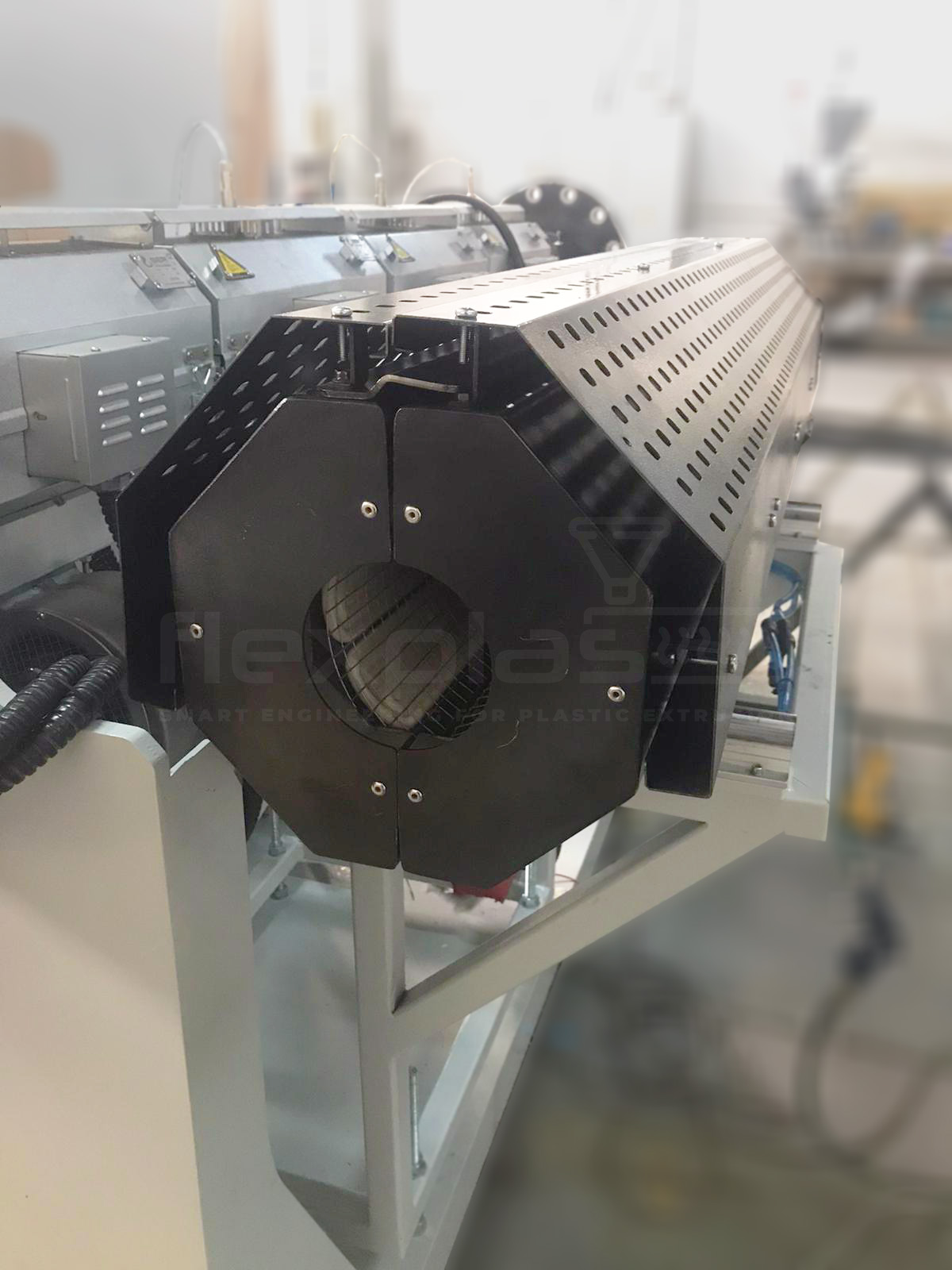

Rapid and uniform heating

Flexplas offers infrared tunnel ovens that are designed to heat rapidly and uniformly the surface of hose, tube, and profile in the extrusion process using targeted high-intensity infrared radiation. We manufacture infrared tunnel oven heaters according to the customer’s application and test them at our facility to ensure that they meet all customer’s technical requirements.

Application

Textile reinforced industrial hose, tube, and cable production

Features

Flexplas Infrared Tunnel Ovens boast many a feature as standard:

- High efficiency with high-intensity infrared radiation and circular reflector efficiently distributing energy inside the heating chamber

- Three-level thermal protection

- Automatic heating control system

- Heating uniformity with special zoning of the total heating surface with separate control for each zone

- Operator-friendly no-touch pneumatic system enabling automatic open/close cover lids

- Emergency stop system for immediate halting the heating process

- Standby mode to maintain the pre-set operating temperature

- Automatic control and alarm reporting a failure of the emitters or a short circuit displaying the corresponding zone of the detected malfunction

- Fast heating to a pre-set operating temperature

- High-alloy stainless steel tunnel internal components

- Specially treated ceramic heaters with more efficient heating, and minimal electrical power consumption

- Optional touch screen control panel

- Heater temperature up to 650 °C

- Compliant with the latest EU/US standards

- Conformity to CE