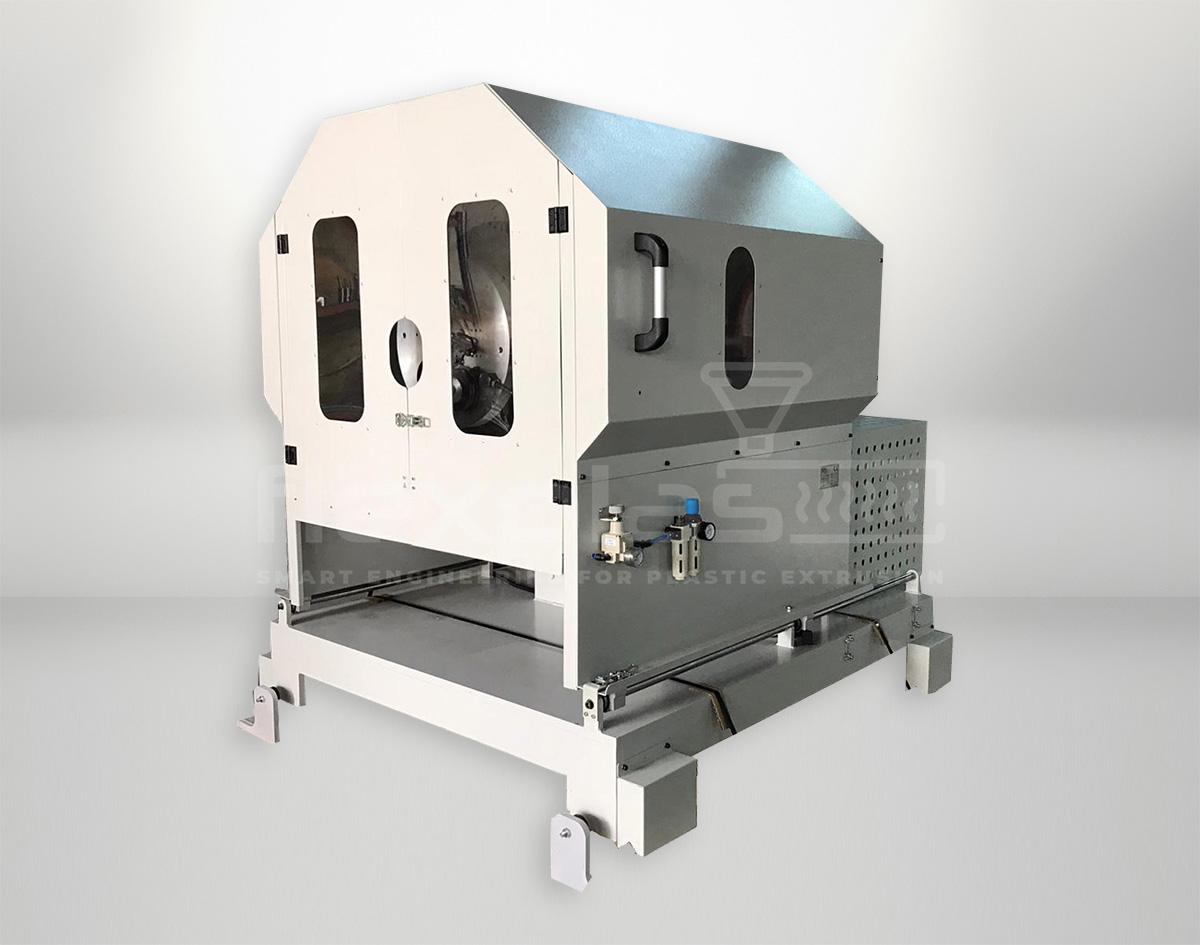

Flexplas Wire Feeding Machine is easily configurated to integrate with your PVC steel wire hose extrusion line. As the most important downstream equipment of your hose production line, Flexplas wire feeding machine offers state-of-the-art specifications to make sure the wire embedded in the hose in the most perfect way possible.

Application

PVC HOSE with STEEL WIRE HELIX reinforcement (plus TEXTILE reinforcement)

Features

Flexplas Wire Feeding Machine boasts many a feature as standard:

- Safe, easy, and time-saving operation

- Constructed as energy efficient

- Smart PLC system with color touch screen for local independent control. Plus, remote (with master control panel) control capability

- Two independent AC servo motors, timing belt pulley drive system (quiet and steady operation)

- Capacity up to 600 kg (modifiable as per extrusion line requirements)

- Speed modifiable as per extrusion line requirements

- Motor-driven sensitive machine positioning adjustment and position read-out

- Making and saving recipe feature

- Emergency reel (drum) brake system with pneumatic control

- Schneider cabin emergency switch with key

- PILZ RFID door safety switches

- PILZ safety PLC

- Fault/Error log

- Fully guarded & interlocked construction for operator safety

- Fully covered chassis with protection lids

- Cabin doors with windows and LED lighting

- Emergency stop button on danger areas and main board according to norms

- Electric board compliant with latest EU standards

- Unique quality wire reels alongside machine to enable reliable wire coiling

- Optional laser wire feed diameter measurement system with camera

- Conformity to the latest EU/US safety standards and CE